what kind of saw do i need to cut 2x6

How to Use a Circular Saw: Long Cuts

Updated: October. 05, 2018

Learn how to safely saw boards freehand, cut plywood with a straightedge guide and build a ripping jig for accurate cut with a circular saw

Learn how to use a circular saw to quickly and accurately cut long boards and plywood. Plus, we've included plans for a handy cutting guide attachment for your saw.

Y'all might also like: TBD

- Time

- Complication

- Price

- An hour or less

- Beginner

- Less than $20

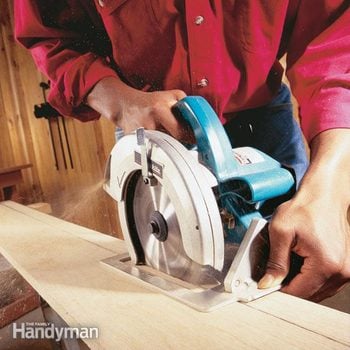

Saw boards freehand

Fifty-fifty if your woodworking is express to an occasional weekend project, you lot'll eventually demand to cut a narrow piece from a long board or sheet of plywood. Sawing long boards is easy if yous own a table saw. But you can also do information technology accurately with a practiced circular saw. In fact, it'due south usually easier to cut long pieces of plywood with a circular saw and a straightedge than to wrestle unwieldy sheets through a table saw. A circular saw won't cut as smoothly as a table saw, merely with a couple of techniques, a little finesse and some practice, you can cut most equally accurately. Sound farfetched? Non really—pros exercise information technology all the time. We'll show y'all how to utilize a circular saw to apace and accurately cutting long boards and plywood, and give you plans for a handy cutting guide attachment for your saw.

Learn how to make perfectly straight cuts using a circular saw in our video tutorial.

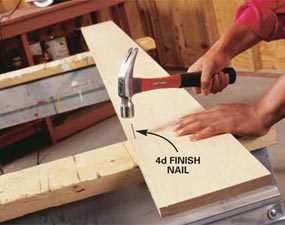

Nail down the board and employ your finger as a guide-carefully!

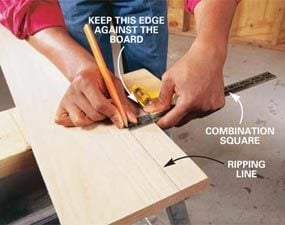

This is a quick way to cut a few 2- to 4-in. strips, just if you take to cut narrow strips oft, build the jig shown on p. 32. For this method, you must nail the board directly to the sawhorses with finish nails (Photo 1). Apply 4d finish nails for 3/four-in. thick forest and 8d finish nails for 1-1/2 in. boards. Then marking the lath and cutting it to width (Photos 2 and iii). This method results in a board of consistent width and parallel sides whether the board you're cut from is straight or kleptomaniacal. If you want to create a straight edge on a crooked lath, mark the board with a straightedge or chalk line instead.

Position your hand on the broad section of the saw shoe, not on the narrow side virtually the blade, and grip the shoe with your forefinger and pollex. Your forefinger acts equally a guide. Every bit yous cut, direct pressure direct ahead through the handle of the saw, and concentrate on the line. If the saw starts to wander from the line, support to about 6 in. behind where you commencement strayed from the line and start again. Before you squeeze the switch to restart the cutting, brand certain the saw blade is perfectly aligned in the kerf and maintain a firm grip in case the blade catches and jerks the saw. Good follow-through is the secret to an authentic finish. Guide the saw across the end of the lath as if the line continued.

Circumspection!

Don't use this method If the lath is splintery or if your finger volition exist closer than three in. from the saw blade.

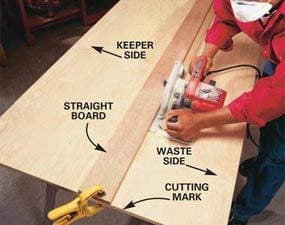

Cut plywood with a straightedge guide

Clamp a straightedge for super-straight cuts

Clamp a perfectly direct lath or metal straightedge to a sheet of plywood to make chiffonier-quality straight cuts. The key is to align the straightedge at exactly the correct distance from the cut line (Photo 2) and go on the saw shoe tight to the straightedge equally you cutting. Photo 1 shows how to brand a test cut and measure the distance from the border of the shoe to the edge of the blade. Mensurate carefully and tape the dimension for reference. Then offset the straightedge from the cutting line by this distance (Photo 2).

When you begin a cutting, barely nick the plywood with the blade to make sure the blade simply touches the outside border of the cutting mark. Move both ends of the straightedge slightly to adjust the cut if necessary, then reclamp it. At the beginning of the cutting, printing the forepart of the saw shoe confronting the straightedge. At the end of the cut, keep the back of the shoe tight until the cutting is complete.

Tip:

Clench the straightedge on the piece of plywood you'll be keeping. This manner, if the saw accidentally wanders from the straightedge, it won't ruin the piece you lot're keeping.

Edifice a Circular Saw Rip Guide

A jig for narrow strips

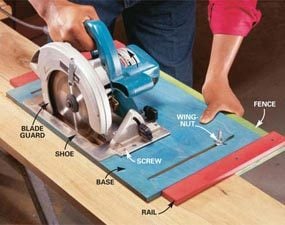

If you don't own a tabular array saw, y'all can build the guide shown in Fig. A and attach information technology to your circular saw. Information technology helps you to cutting narrow strips (one/2 in. to 6 in. wide) with near table-saw precision (Photo 1). You may have to modify it to fit your saw'due south shoe. It takes about an hour to build this round saw rip guide.

Cutting the plywood base and pieces carefully to make certain they accept parallel sides and foursquare corners. Make the slots and the pigsty for the bract and blade guard past first drilling three/8-in. holes in the corners and and so cutting betwixt them with a jigsaw. Ready the base over the fence and align ane long edge. And so snug the rails upward to the sides of the base of operations and screw them to the fence with 7/eight-in. screws. The completed argue assembly should fit snugly and slide hands. Connect the debate to the base with carriage bolts and attach the saw shoe to the base with small screws. Drill v/32-in. holes in your saw shoe and attach the guide with five/8-in. screws.

Figure A: Jig for Narrow Strips

This guide allows you lot to cut narrow strips with your circular saw.

Safety First

Making long cuts tin can be dangerous. Earlier yous attempt information technology, read the following prophylactic precautions.

- Wear safety glasses and hearing protection and avoid loose-fitting clothes. Tie long hair dorsum.

- Set up the saw blade to cut about 1/4 in. deeper than the wood's thickness.

- Secure boards less than half dozen in. wide with nails and wider boards with clamps.

- Stand beside, never backside, the blade when yous're cutting. Keep bystanders away from the area behind the saw.

- Wedge the saw cut open with a shim if the lath starts to pinch the blade and cause it to bind.

- Make certain the blade guard is operating freely. Never cake or wedge it in the raised position.

Video: How to Cutting Direct With a Circular Saw

Jeff Gorton, an editor for The Family unit Handyman, will show you lot how to brand perfectly straight cuts using a circular saw. You will apply this circular saw jig over and over once again.

Required Tools for this Project

Have the necessary tools for this DIY project lined upward earlier yous start—you lot'll save time and frustration.

Spring Clamps

Required Materials for this Projection

Avoid terminal-minute shopping trips by having all your materials set ahead of time. Here's a list.

Originally Published: October 03, 2018

johnsonthable1952.blogspot.com

Source: https://www.familyhandyman.com/project/how-to-use-a-circular-saw-long-cuts/

Enregistrer un commentaire for "what kind of saw do i need to cut 2x6"